National Engravers

National Engravers Australia website

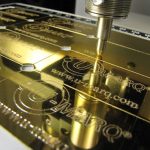

Industrial Engraving services by National Engravers Australia.

Our partner, National Engravers Australia, is part of the Mackay Trophy House group of companies.

National Engravers Australia engraves all your industrial equipment.

Whatever the material, contact National Engravers Australia today for all your industrial engraving needs.

- Brass

- Stainless Steel

- Aluminium

- Plastic

- Labels

- Signs

- Padlocks

- Compliance Plates

- Electrical

Industrial engraving is a process of permanently marking a material with text, logos, or other designs.

It is a versatile process that can be used on a variety of materials, including metal, plastic, wood, glass, and stone. Industrial engraving is often used to create identification tags, nameplates, warning labels, and other items that need to be durable and long-lasting.

In the mining and resources industry, safety, efficiency, and accurate identification are of paramount importance. Industrial engraving plays a crucial role in meeting these requirements. By permanently marking various equipment, components, and materials, industrial engraving ensures clear identification, traceability, and adherence to safety regulations. This informative piece will explore the significance of industrial engraving in the mining and resources industry, its benefits, and the different applications within this sector.

Identification and Traceability:

Industrial engraving provides durable and permanent markings on a wide range of materials, including metal, plastic, and stone. Equipment and components such as valves, pipes, gauges, and tools can be clearly labeled with unique identifiers, part numbers, serial numbers, and other essential information. This facilitates easy identification, traceability, and maintenance of equipment throughout its lifecycle.

Safety Compliance:

Engraved safety labels and signs play a vital role in maintaining a safe working environment. Hazardous areas, restricted zones, emergency exits, and important instructions can be effectively communicated through engraved signage. Engraved warning labels on machinery and equipment alert workers to potential dangers and precautionary measures, thereby reducing the risk of accidents.

Enhanced Efficiency:

Engraved markings enable quick and accurate identification of equipment and components, streamlining inventory management, maintenance, and repairs. By eliminating guesswork, workers can locate the required items promptly, leading to increased operational efficiency and reduced downtime.

Durability and Longevity:

Industrial engraving utilizes various techniques such as laser engraving, rotary engraving, and chemical etching, which create permanent markings that withstand harsh conditions, including extreme temperatures, abrasion, and chemical exposure. These durable engravings ensure that crucial information remains intact throughout the lifespan of equipment, minimizing the need for frequent replacements.

Cost-effectiveness:

Investing in industrial engraving can lead to long-term cost savings. Clear identification and traceability provided by engraved markings minimize the chances of misplaced or lost equipment. This reduces downtime, inventory costs, and replacement expenses. Additionally, by complying with safety regulations, engraving helps avoid fines and penalties associated with non-compliance.

Asset Tracking and Inventory Management:

Engraved asset tags and labels with unique identifiers assist in efficient asset tracking and inventory management. By scanning or reading the engraved codes, workers can access relevant information about the equipment, such as its service history, maintenance records, and location.

Industrial engraving is an invaluable tool for the mining and resources industry, providing durable and clear markings that enhance safety, efficiency, and compliance. By utilizing various engraving techniques and applying them to equipment, components, safety signage, and markers, mining.